Class Approved Valve Services

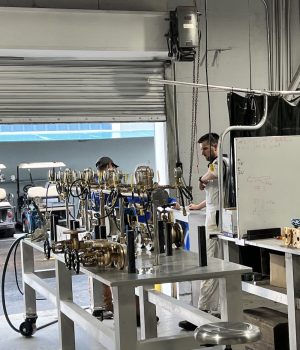

Revolutionary Marine Valve Services: Test Up to 16 Valves Simultaneously

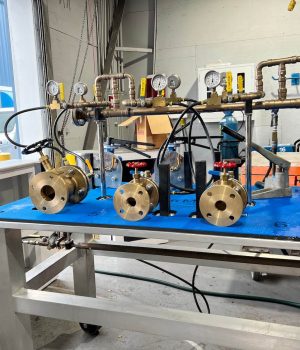

Welcome to American Marine Repair (AMR), where we redefine excellence in marine valve services, including specialized care for thru hull valves. Our class-approved valve services, encompassing both valve testing and valve replacement, set new industry standards. Our innovative approach, capable of testing up to 16 valves simultaneously, marks a significant leap from traditional, one-by-one testing methods.

Efficiency and cost-effectiveness are the cornerstones of our practice. Our advanced, class-approved equipment is specifically designed to enhance the valve service process, providing significant time and financial savings. We adhere strictly to rigorous class standards, accredited by respected authorities like Lloyds, RINA, and ABS, ensuring every valve, particularly specialized thru hull valves, meets the highest levels of quality and safety.

Embrace the future with American Marine Repair, the industry’s sole provider of these advanced valve services. Our state-of-the-art technology guarantees precise, rapid, and highly efficient results.

Choose American Marine Repair for your valve service needs and enjoy:

- Simultaneous testing of up to 16 valves, ensuring unparalleled efficiency.

- Significant time and cost reductions with our optimized valve services.

- Class approval from esteemed institutions like Lloyds, RINA, and ABS.

- Dependable, accurate results, adhering to the strictest standards.

Experience our unmatched class-approved valve service capabilities today!

Understanding Valves in Motor Yachts

Valves are essential for managing fluid direction, flow, and pressure in boat systems, a critical aspect for the safety and performance of motor yachts. Integral to a boat’s piping system, valves, especially thru hull valves, play a key role in controlling different pressures and flows within various onboard systems. This makes valve services vital to your boat’s safety and wellbeing.

- Initiating or stopping fluid flow.

- Regulating fluid flow volumes.

- Directing fluid flow, crucial for preventing backflow.

- Controlling the pressure within the flow.

- Alleviating pressure in pipe systems.

- Mixing different fluids or solids.

Expert Maintenance and Valve Replacement: Navigating Your Yacht’s Essential Valve Systems

We cover all aspects of the different valve systems in a yacht, from gate valves to butterfly valves, globe valves, and relief valves. Our thorough valve maintenance and replacement services are essential for boat repair and upkeep, ensuring your vessel’s optimal performance and safety.

Gate Valves

Gate Valves are common in motor vessels, they control liquid flow like a gate. Simple in design, they are crucial for efficient operation.

Butterfly Valves

Butterfly Valves are ideal for lower pressure systems. Their lightweight design and cost-effectiveness make them a smart choice for fire-water and wastewater lines.

Globe Valves

Globe Valves are best for precise flow control, used in both medium and high-pressure systems.

Relief Valves

Relief Valves are vital for vessel safety. These valves relieve pipe pressure, adjustable for various operational needs.

Four Main Groups of Valves

- Thru-Hull Valves on Supply Lines

- Domestic Water Valves

- Isolation Valves on Drainage Lines

- Fuel System Valves

Thru Hull Valves on Supply Lines. Usually, quarter-turn ball valves of bronze or Delrin. Located below the water line, the proper functioning of these valves is critical to the vessel’s safety. If these valves fail, water could come into the boat and possibly sink it.

Domestic Water Valves. All motor vessels with pressurized water (faucets, dishwashers, showers, etc.) have valves between tank and use. These valves are responsible for keeping your fresh water from being pumped into the bilge or wherever it goes on your boat. The isolation valves on the supply lines are quarter-turn ball valves.

Isolation Valves on Drainage Lines. These valves are on the drainage lines. They are hoses that penetrate the hull to allow grey, black, and seawater (from things that are seawater cooled, like a/c or refrigeration) to be pumped overboard. The point of penetration is typically above or just on the water line. Some are quarter-turn ball valves and are there to prevent water from being pumped back into the boat, particularly in bad weather.

Fuel System Valves. Many fuel systems have valves as well. These isolate the tank from the things that use fuel in case of fire or leaks. In addition, if there are dual-parallel fuel filters, there will be a valve to direct the flow from one filter to the other.

Why Choose AMR for Your Valve Service and Valve Replacement Needs

AMR simplifies the complexity of valve inspections and testing. Our expertise and state-of-the-art equipment, especially for thru hull valves and valve replacements, ensure an efficient and reliable process. Whether it’s for your boats 5-year survey, 10 year survey or 20-year survey, we are here to make the process easy and efficient.

Our quick, hassle-free process:

- Collect and test valves at our facility or directly from your vessel.

- Conduct onsite testing with a class surveyor present.

- Reinstall approved valves back on your vessel.

- Provide all necessary class documentation for approved valves.

- Order new valves and conduct replacements when necessary.

For advanced marine valve services, including valve testing and valve replacement, reach out to American Marine Repair.